Since the establishment of IPROLAM S.A. Bucharest, the main activity focus was the embodiment of manufacturing technologies for sections and plants for milling ferrous and nonferrous products, reflected in the preparation of technical documentation and execution of operations for mechanical, hydraulic, lubrication, electrical, automation, software, industrial and civil construction projects.

Thereafter, in the 90's, IPROLAM extended and diversified their research area responding to the increasing demands of its customers, through tackling new activities with an increase in difficulty and responsibility, for example, General supplier of equipment, technological equipment and services, as well as the general contractor for the execution of complex work delivered "turnkey".

The most recent and relevant works of General Supplier accomplished by Iprolam S.A. can be found at the NEWS section.

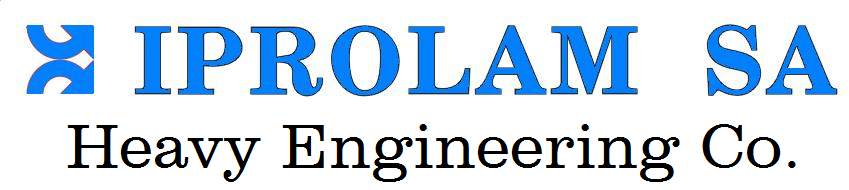

- MAN INDUSTRIES, ESSAR (INDIA), UZINEXPORT PENTRU HUNAN SHENGLI XIANGGANG STEEL PIPE Co Ltd CHINA- Mechanical expander for welded pipes;

- GRÄEBENER (GERMANIA), MAN INDUSTRIES ANJAR (INDIA)-Installation of chamfered pipe ends;

- TRUBINVEST GAZPROM (RUSIA), TENARIS SILCOTUB ZALAU- Press for testing "Hydrotester 1300 bar" pipes;

- MAN INDUSTRIES (INDIA), ESSAR (INDIA), UZINEXPORT PENTRU HUNAN SHENGLI XIANGGANG STEEL PIPE Co Ltd CHINA - Milling machine for sheet edges;

- VICTORIA MICHELIN FLORESTI - Calender roller conveyors and conveying the material for pickup line calendering B2;

- JESCO (SAUDI ARABIA), SINARSKIJ ROEHRENWERK, TAGANROGSKY METALLURGIEWERK, VOLZHSKY PIPE PLANT OJSC, WYKSA (EMAG FOR RUSSIA), TIANJIN PIPE GROUP CORPORATION (EMAG FOR CHINA) - Complete system for calibrating pipes for oil use + full inspection system;

- ALRO SLATINA - Additional device for leveling steel sheets to the 50 MN Stretcher;

- ERDEMIR TARGOVISTE - Automation system modernization for the electrical strip continuous annealing line (B2);

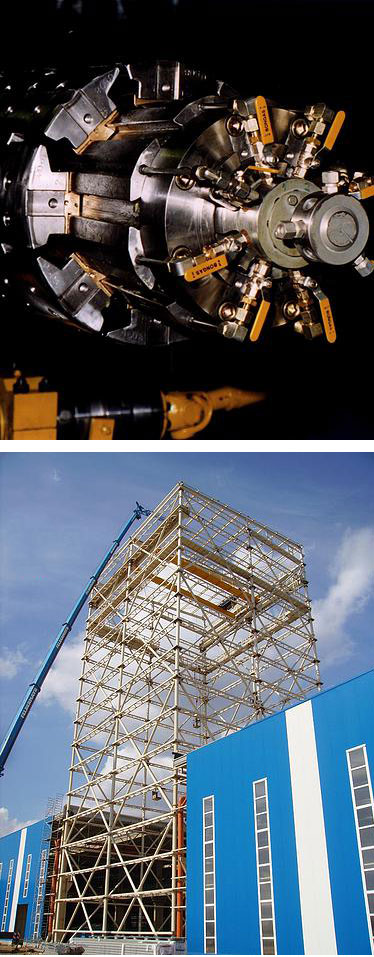

The most recent and relevant works of General Entrepreneur accomplished by IPROLAM S.A. are the following:

- RIGIPS TURDA – gypsum roasting installation;

- METROM BRASOV - Modernization of the cold rolling mill Ø 450;

- SC LAROMET BRASOV - Foundation execution for CBA press in the GREAT HALL - Brasov working site;

- ARCELORMITTAL ROMAN - Mill for removing dross from pipe installations in 20"

- IMSAT BUCHAREST - Rehabilitation works for the Production Hall- Improvement of inner deposits - Container factory Giurgiu;

- IMSAT BUCHAREST - Improvement of the SEE Bay - Giurgiu working site